Thread machining right down the line

The Austrian carbide and tool specialist Boehlerit continues to move towards becoming a full-range supplier and develops balanced geometries, with the aim of delivering top performance over a very wide range of materials and applications. This results in efficient and highly productive tool solutions with a comprehensive variety of products.

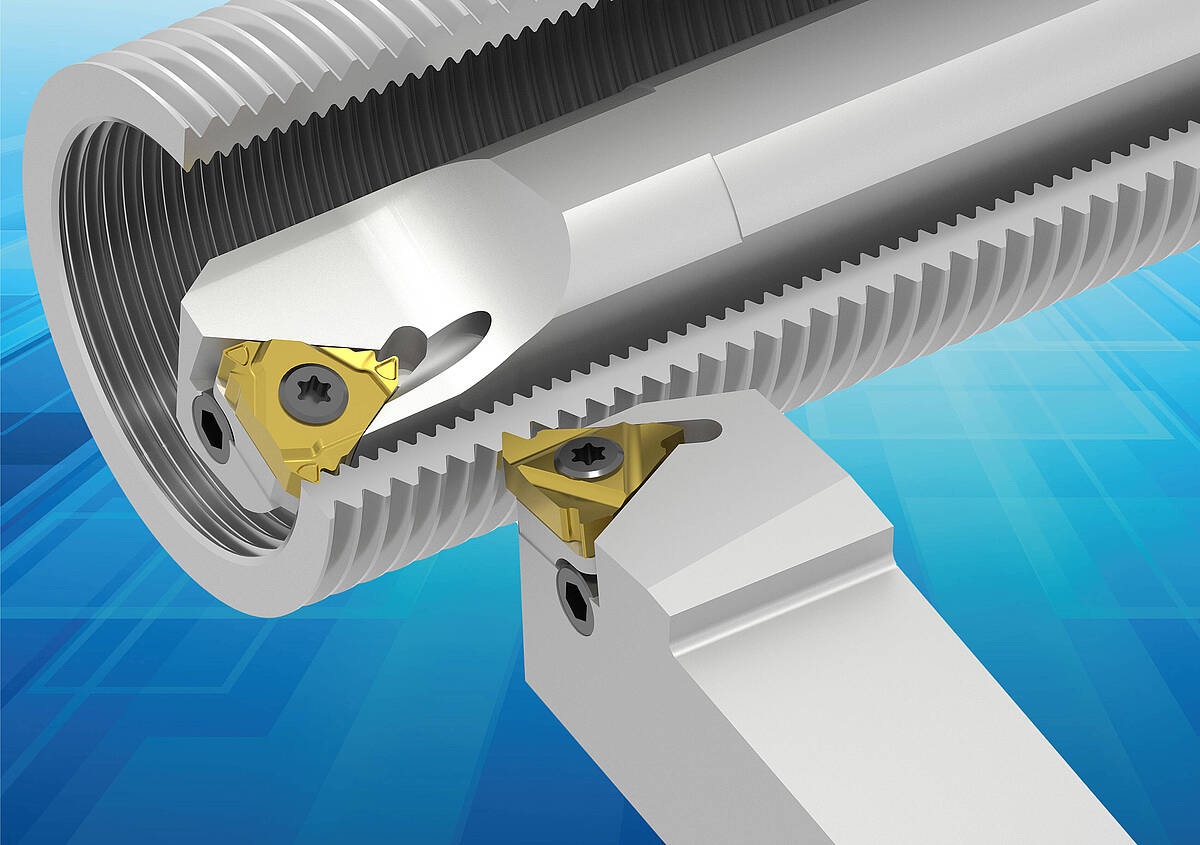

BCU20T - Outstanding performance in thread turning even under difficult conditions

With the BCU20T grade, Boehlerit, the specialist for carbides and tools, is presenting a new ultra-fine grain grade for thread turning. It has a TiAlN coating and is perfectly suited for general use. The BCU20T grade is a reliable option for demanding applications as it has excellent fracture toughness even under difficult conditions. In addition, Boehlerit has expanded its threading range to include direct-pressed indexable inserts. These are available in various part profiles with 55° and 60° as well as in ISO metric, American UN, Whitworth, NPT, BSPT and API round and represent an economical solution for threading applications. The direct-pressed plates can be easily identified by the abbreviation ‘BD’ and are characterised by excellent performance and high quality.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Tapping

The four new Boehlerit thread machining lines made of especially wear-resistant high-performance high-speed steel, in combination with the in-house coating know-how, are setting new standards for the machining of complex components and materials.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Innovative thread rolling process with Wagner rolling systems powered by Boehlerit: Highest precision and efficiency

The Styrian carbide and tool specialist Boehlerit has concluded a worldwide sales co-operation (with the exception of Germany) for thread rolling systems with Wagner Tooling Systems Baublies GmbH from Pliezhausen in Germany. Thread rolling is an advanced technique for producing threads by cold forming the material using high pressure. A permanent plastic deformation is achieved, whereby thread rolling precisely displaces the material from the thread core and directs it towards the thread tips. Thanks to this method, the fibre flow in the metal is not interrupted, but merely changed in order to produce threads with high strength, profile and dimensional accuracy.

Extended product line of AXIAL thread rolling systems HELIX

Wagner rolling systems are renowned for producing threads with high surface quality, tensile strength and load carrying capacity and are available in a variety of designs. The HELIX and RS axial rolling systems and the tangential rolling systems each offer specific advantages for different applications: The HELIX systems are compact and have large roll diameters, while the RS systems feature interchangeable roll holders. The tangential rolling systems allow efficient threading even behind a collar and can be used in the tightest of spaces.

Customised solutions are also available for optimum threading results. The systems are available in various sizes and are ideal for workpieces from M1.6 to MF75 mm.

Boehlerit GmbH & Co. KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

API-Thread machining

Boehlerit offers ideal solutions for your application in the field of API threading. Whether face turning, chamfering, copying, roughing or peeling - nearly all machining solutions can be covered.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria