THETAtec 25N Feed:

High feed milling redefined

Boehlerit has already set standards with its positive high feed systems. The company is now expanding its portfolio of high feed products and introducing its new tool concept on a negative basis. Like its positive systems, the innovative THETAtec 25N Feed tool system enables higher cutting rates and thus maximum performance and efficiency in a single application.

High-performance cutting (HPC) is a proven method for performing machining operations with high removal rates, as required for roughing steel, cast iron and stainless materials. Maximum feed rates reduce machine occupancy times and maximise the volume of chips removed. This is advantageous in view of the increasingly important cost factors in the area of process energy efficiency and creates additional production capacity. High-feed milling results in increased productivity and, at the same time, a measurable reduction in costs.

Boehlerit GmbH & Co. KG

Segment Cutting Tools

Werk VI-Straße 100

A-8605 Kapfenberg

Österreich

Extended product line of AXIAL thread rolling systems HELIX:

Efficiency, flexibility and durability combined

Boehlerit, the Styrian carbide and tool specialist, has entered into a worldwide sales cooperation (with the exception of Germany) for thread rolling systems with Wagner Tooling Systems Baublies GmbH of Pliezhausen, Germany. Thread rolling is an advanced technique for producing threads by cold forming the material under high pressure. Permanent plastic deformation is achieved, with thread rolling precisely displacing the material from the thread core and directing it towards the thread tips. This process does not interrupt the flow of fibres in the metal, but merely alters it to produce threads of high strength, profile and dimensional accuracy.

Wagner rolling systems are renowned for producing threads with high surface quality, tensile strength and load carrying capacity and are available in a variety of designs. The HELIX and RS axial rolling systems and the tangential rolling systems each offer specific advantages for different applications: The HELIX systems are compact and have large roll diameters, while the RS systems feature interchangeable roll holders. The tangential rolling systems allow efficient threading even behind a collar and can be used in the tightest of spaces.

Customised solutions are also available for optimum threading results. The systems are available in various sizes and are ideal for workpieces from M1.6 to MF75 mm.

Boehlerit GmbH & Co. KG

Segment Cutting Tools

Werk VI-Straße 100

A-8605 Kapfenberg

Austria

With Sawtec brazed, Boehlerit is responding to the increasing demands in modern manufacturing processes, where the highest cutting quality and long tool life are required. Thanks to the brazed design, in which the saw teeth are firmly connected to the saw blade body using high-performance brazing systems, outstanding stability and high resistance to the extreme forces during the cutting process are ensured.

Precision for the highest demands

The new brazed saw blades not only impress with their precise workmanship, but also with the targeted selection of high-quality materials and innovative manufacturing techniques. This results in a high cutting quality with minimal wear, which increases productivity and reduces downtime.

Wide range of applications

The brazed saw blades from Boehlerit are suitable for a wide range of applications and cover a broad spectrum from soft to harder materials. To meet the specific needs of different industries, the saw blades are available in diameters from 250 to 460 mm and with a cutting width of 2 to 2.8 mm. Other dimensions and cutting widths can be provided on request.

Carbide as the ideal material for sophisticated structural components

The use of carbide as a construction element has become indispensable in various sectors such as the chemical industry, plastics production, the food industry, blasting technology, the recycling industry and the health and hygiene sector. Carbide is characterised in particular by its wear resistance and is therefore a reliable option for components that have to withstand extreme loads.

The carbide and tool specialist Boehlerit is presenting its latest ready-to-install cutting systems, which have been specially developed for existing and new production lines in the FemininCare and BabyCare sectors as well as other areas of application in the hygiene industry. The cutting systems offer the option of converting from steel/HSS to carbide in order to sustainably increase efficiency and service life.

Boehlerit GmbH & Co.KG

Segment Wear protection & semi-finished products

Werk VI-Straße 100

8605 Kapfenberg

Austria

Bulltec Turn - the innovative solution for more efficient

and economical turning of superalloys, nickel-based alloys and stainless materials

The Bulltec Turn high-end indexable insert, equipped with six cutting edges, offers numerous advantages for machining technology. The insert thickness of 9 mm ensures improved insert stability, which means that a longer insert life can be achieved. The specially developed macro geometry has been optimised for machining superalloys, nickel-based alloys and stainless materials and ensures high performance and precision.

The ability to choose between MM geometries for medium machining and RM geometries for roughing applications allows users to customise the insert to the specific requirements of their machining processes. This leads to the best possible results and efficient machining.

Boehlerit GmbH & Co. KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Innovative thread rolling process with Wagner rolling systems powered by Boehlerit:

Highest precision and efficiency

The Styrian carbide and tool specialist Boehlerit has concluded a worldwide sales co-operation (with the exception of Germany) for thread rolling systems with Wagner Tooling Systems Baublies GmbH from Pliezhausen in Germany. Thread rolling is an advanced technique for producing threads by cold forming the material using high pressure. A permanent plastic deformation is achieved, whereby thread rolling precisely displaces the material from the thread core and directs it towards the thread tips. Thanks to this method, the fibre flow in the metal is not interrupted, but merely changed in order to produce threads with high strength, profile and dimensional accuracy.

Sets new standards for productivity and efficiency

Boehlerit, the carbide and tool specialist, is launching a new drilling tool on the market that optimises the production process and increases efficiency. The innovative Drilltec impresses with high cutting and feed speeds, a high metal removal rate and outstanding drilling quality. With the option of using 4 cutting edges, the Drilltec is extremely economical and guarantees a long tool life and cost-reduced tool utilisation. The Drilltec is available in 2xD, 3xD, 4xD and 5xD sizes and therefore offers flexibility for different requirements.

Boehlerit GmbH & Co. KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Highest productivity with the smallest drill holes

The new Microtec tools for internal machining with additional holder are an innovative solution for turning small and narrow bores. The new Microtec tools consist of two parts: the clamping body and the drill shank. The clamping body is permanently mounted in the machine and has a holder for the drill shank. The boring bar can be replaced without removing the entire holder, making it easier and quicker to change the indexable insert. The five available boring bars are available for different drilling diameters and cutting edge angles and can be used with the existing CCGT030102, DCGT and VCGT minitools.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Excellent Supplier Award for Boehlerit Mexico

For the second year in a row, Boehlerit Mexico, a leading manufacturer of cutting tools, has been recognised as an ‘Excellent Supplier’ by its long-standing business partner MACIMEX. This prestigious award recognises Boehlerit's continued excellence and exceptional commitment to working with MACIMEX.

Boehlerit received the "Work and Family" certificate

As part of our corporate culture, it is important to us that private and business life harmonise well. Topics such as flexible working hours or mobile working, adapted to the respective life situation, make a central contribution to being able to combine all tasks well.

Satisfaction as an important benchmark

The importance of family-friendliness will continue to be promoted and intensified on a professional and structured basis in the future. The holistic human resources strategy that has been developed is intended to improve the framework conditions for each individual and to lead to an optimal reconciliation of private and professional life in increasingly challenging times. In this way, we can sustainably keep the satisfaction of our employees always in focus.

We are very proud of the certification and thank everyone who supported us!

Foto © Harald Schlossko

Boehlerit received the "Work and Family" certificate

As part of our corporate culture, it is important to us that private and business life harmonise well. Topics such as flexible working hours or mobile working, adapted to the respective life situation, make a central contribution to being able to combine all tasks well.

Satisfaction as an important benchmark

The importance of family-friendliness will continue to be promoted and intensified on a professional and structured basis in the future. The holistic human resources strategy that has been developed is intended to improve the framework conditions for each individual and to lead to an optimal reconciliation of private and professional life in increasingly challenging times. In this way, we can sustainably keep the satisfaction of our employees always in focus.

We are very proud of the certification and thank everyone who supported us!

Foto © Harald Schlossko

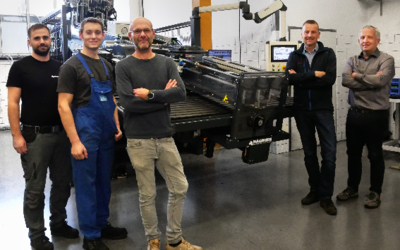

New 4.0 ram extruder for innovative carbide products

Boehlerit has recently purchased one of the most developed ram extruders for the carbide manufacture of complex profiles aand rods.

Read more about it here!

Boehlerit is the winner of the Styrian Export Award 2022

The award in the category of large companies is based on the export success story of carbide-tipped wear parts for soil cultivation and mechanical weed control.

Read more about it here!

Technological leap ahead for the indexable insert grinding department, thanks to investment in precision

To continue to fulfil the quality requirements for increasingly small and precise indexable inserts used in small parts manufacturing, in particular in medical engineering and in the watchmaking industry, Boehlerit has invested in 5 state-ofthe-art Agathon peripheral grinding

machines.

Technological edge through investments in the sintering workshop

Boehlerit, the Austrian expert for carbides and cutting materials, wants to stay ahead of technological developments in future and has thus committed to a growth programme that envisages investments in sales, products and manufacturing. Ever-more sophisticated materials place high demands on tools, with quality requirements also becoming more stringent all the time.

Inside Boehlerit

The latest technologies and the highest quality standards for our high-end products.

Hard facts for best results

Technological edge through investments in the sintering workshop

Boehlerit, the Austrian expert for carbides and cutting materials, wants to stay ahead of technological developments in future and has thus committed to a growth programme that envisages investments in sales, products and manufacturing. Ever-more sophisticated materials place high demands on tools, with quality requirements also becoming more stringent all the time.

COVID-19: Information for Customers

Boehlerit has taken on responsibility in the fight against the spread of COVID-19 infections, whereby our top priority is to ensure the safety of our employees and business partners and to keep the risk of infection to an absolute minimum. At the same time, we are doing everything within our power to maintain uninterrupted production at all locations in order to meet all our delivery commitments and supply on time.

Boehlerit as official sponsor of EuroSkills 2021

We are part of it: We are proud to announce that we will be supporting EuroSkills, the European vocational championships, to be held in Graz from 06th to 10th January 2021, as an official sponsor. By making this commitment, we not only demonstrate our interest in a sound education for young people, but also play an active role in supporting these young skilled workers. EuroSkills is an international event at which around 600 competitors in 45 skills and trades compete over three days for the gold medal and the title as European champion in their own skill or trade. It is this very incredible motivation and ambition that make up this Skills spirit, which we at Boehlerit are delighted to support.

Plant-optimised dedusting plant

for shaping processes

The implementation of the dedusting plant is 90 % financed by funds from the IWB/EFRE regional programme.

More information about this project can be found here.